-

tel : +8618150976625

-

E-mail : Hello@MicrofiberLeather.com

tel : +8618150976625

E-mail : Hello@MicrofiberLeather.com

PU football factory origins trace back to the competitive spirit sparked by Puma’s separation from the Dassler Brothers, which drove innovation in sports equipment. Sialkot became a central hub for soccer ball production, shaping the global distribution of footballs. The transition from leather to polyurethane transformed production, making footballs more durable and accessible. Today, factories in Pakistan, China, and India meet rising demand and support worldwide football culture.

PU football factories began with Puma's innovation after the Dassler Brothers split, driving competition in sports equipment.

Sialkot, Pakistan, produces about 70% of the world's hand-stitched footballs, combining traditional craftsmanship with modern materials.

The shift from leather to polyurethane (PU) made footballs more durable, water-resistant, and affordable for players worldwide.

Automation and advanced technology have transformed football production, increasing efficiency and reducing costs.

The global demand for footballs has led to the growth of factories in China and India, expanding the industry's reach.

Job creation in football manufacturing has improved living standards in regions like Sialkot, supporting local economies.

Affordable footballs promote physical activity and community engagement, making the sport accessible to more people.

Sustainability efforts are increasing, with factories exploring eco-friendly materials and recycling programs to reduce environmental impact.

The pu football factory story began with the rivalry between two brothers in Germany. Rudolf and Adolf Dassler started their journey together, creating sports shoes in the early 20th century. Their partnership ended, and Rudolf founded Puma. This split fueled competition and innovation in the sports equipment industry. Puma quickly became a leader in football manufacturing, introducing new materials and designs. The company’s focus on quality and performance set high standards for the industry. Puma’s influence reached beyond Germany, inspiring other brands to improve their own soccer ball production methods.

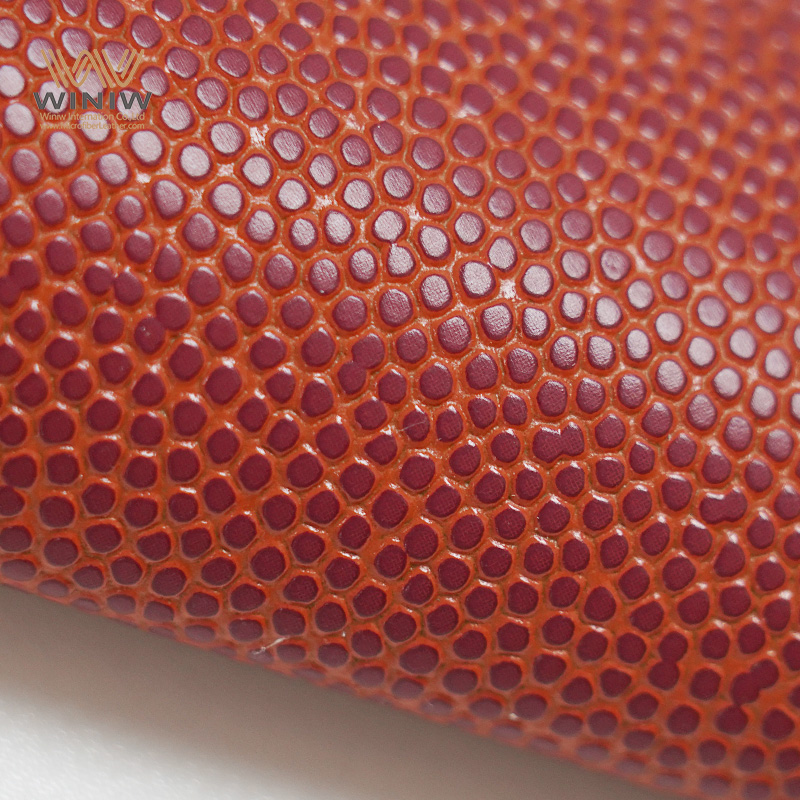

The industry saw rapid growth as football gained popularity worldwide. Companies invested in research and development to create better products. The pu football factory emerged as a response to the need for more durable and affordable footballs. Polyurethane replaced traditional leather, offering improved water resistance and consistent performance. This shift marked a turning point in soccer ball manufacturing. Factories adopted new techniques and machinery, increasing production capacity and efficiency. The industry expanded its reach, supplying footballs to clubs, schools, and international tournaments.

Sialkot, a city in Pakistan, became a powerhouse in the pu football factory landscape. Its reputation grew due to skilled craftsmanship and a strong tradition in hand-stitched footballs. Sialkot’s factories combined traditional methods with modern materials like synthetic PU and PVC. The city’s footballs gained recognition for their quality and affordability. This reputation led to increased demand from international markets.

Sialkot produces about 70% of the world’s hand-stitched footballs.

Local artisans blend old techniques with new technology.

The city’s products remain both affordable and high in quality.

Sialkot’s success in football manufacturing transformed the local economy and set a global standard for soccer ball production.

Forward Sports, based in Sialkot, played a key role in the city’s rise. The company became a major supplier for fifa tournaments. Forward Sports focused on innovation and quality control, earning trust from top organizations. Their partnership with fifa showcased Sialkot’s ability to meet strict international standards. This collaboration highlighted the city’s importance in the pu football factory industry. Forward Sports continues to lead in production, supporting the growth of football around the world.

Note: Sialkot’s journey from a local craft center to a global leader in soccer ball manufacturing shows the power of innovation and tradition working together.

The history of football manufacturing shows a clear shift from leather to polyurethane (PU). Early footballs used leather panels, which absorbed water and became heavy during play. Manufacturers searched for better materials to improve performance and durability. Polyurethane offered several advantages. It resisted water, kept its shape, and provided a consistent touch. Players noticed that PU footballs performed well in all weather conditions. PU also allowed for brighter colors and more creative designs, making the game more exciting for fans and players.

Note: Polyurethane changed the way people viewed football equipment. It set a new standard for quality and reliability.

The introduction of PU led to major changes in production. Factories adopted new machinery to handle synthetic materials. Workers learned to cut, shape, and bond PU panels with precision. This process reduced waste and improved efficiency. Companies could now produce more footballs in less time. The use of PU also made it easier to meet international standards for size and weight. As a result, football manufacturing became more consistent and reliable.

In the early days of soccer ball manufacturing, skilled workers hand-stitched each panel. This method required patience and attention to detail. Sialkot’s artisans became famous for their craftsmanship. Over time, factories introduced machines to speed up production. Machines could stitch panels faster and with greater accuracy. This shift allowed companies to meet the growing demand for footballs around the world.

Hand-stitching produced high-quality balls but limited output.

Machine production increased efficiency and lowered costs.

Modern factories use a mix of both methods for different types of footballs.

Today, most footballs come from automated production lines. However, some premium balls still use hand-stitching for top-level matches. The evolution from hand-stitching to machine production marks a key chapter in the history of football manufacturing.

The global football industry saw a major shift when factories began operating in China and India. These countries offered large labor forces and lower manufacturing costs. Companies recognized the potential for increased soccer ball production. They built new facilities and trained workers in advanced techniques. China quickly became a leader in mass production. India followed by focusing on both quality and quantity. This expansion allowed brands to meet the growing demand for footballs in new markets.

Fact: China and India now produce millions of footballs each year for both local and international markets.

The industry did not stop at building factories. Companies created complex supply chains to move materials and finished products around the world. They partnered with shipping firms and logistics experts. This network made it possible to export footballs to every continent. Sialkot remained a key supplier, but the reach of the industry became truly global. The ability to deliver high-quality footballs quickly helped the sport grow in popularity.

Companies reduced delivery times.

Brands reached new customers in remote regions.

The global football industry became more connected than ever before.

Technology played a major role in the worldwide spread of football factories. Machines improved the speed and accuracy of soccer ball manufacturing. New materials made footballs more durable and consistent. Automation allowed factories to increase production without sacrificing quality. Companies invested in research to develop better designs. These innovations helped the industry meet the strict standards set by organizations like FIFA.

Note: Advances in technology continue to shape the future of soccer ball production.

The popularity of football soared in every corner of the world. More people wanted to play, watch, and own footballs. This rising demand pushed factories to increase production. Export numbers grew as countries hosted international tournaments and local leagues. The industry responded by building more factories and hiring more workers. Soccer ball production became a symbol of economic growth in many regions.

Football became the world’s most popular sport.

The industry created jobs and supported local economies.

Global events like the FIFA World Cup fueled even greater demand.

The expansion of football factories shows how technology, trade, and passion for the game can transform an industry. The journey from local workshops to a global network highlights the power of innovation and teamwork.

Pakistan leads the world in football production. The city of Sialkot stands as the heart of soccer ball manufacturing. Local factories produce high-quality footballs for international markets. Workers in Sialkot use advanced techniques and strict quality controls. The region supplies footballs for major tournaments, including those with fifa certification. Many global brands rely on Pakistan for consistent supply and reliable distribution.

Fact: Sialkot’s factories produce millions of footballs each year, supporting the sport’s growth worldwide.

Pakistan’s industry benefits from skilled labor and a long tradition of craftsmanship. The country’s reputation for excellence in soccer ball production attracts buyers from every continent. Sialkot’s leadership in the industry remains unmatched.

China and India have expanded their roles in football production. Both countries offer large workforces and modern manufacturing facilities. Companies in China focus on automation and scale. India invests in both technology and training to improve output. These nations have increased their share of the global market.

A comparison of production strengths:

|

Country |

Strengths |

Market Focus |

|---|---|---|

|

Pakistan |

Craftsmanship, quality |

International |

|

China |

Automation, volume |

Mass production |

|

India |

Training, innovation |

Regional & export |

China and India’s industry continues to grow. Their factories supply footballs for schools, clubs, and local leagues. The expansion of production in these regions supports the rising demand for the sport.

Forward Sports, based in Sialkot, sets the standard for high-quality footballs. The company holds partnerships with fifa and supplies balls for major tournaments. Forward Sports uses advanced machinery and strict quality checks. Their commitment to innovation keeps them at the forefront of the industry.

Other leading factories include:

Select Sport (Denmark): Known for durable designs and global distribution.

Mitre (UK): Focuses on technology and performance.

Cosco (India): Supplies footballs for schools and regional competitions.

Adidas (Germany): Partners with factories worldwide for soccer ball production.

Tip: Factories with fifa certification must meet rigorous standards for size, weight, and durability.

These hubs drive the industry forward. They invest in research and development to improve football production. The global network of factories ensures that players everywhere have access to reliable equipment.

The current landscape of football production reflects a blend of tradition, technology, and international cooperation. Pakistan’s dominance, combined with the growth of China and India, shapes the future of the industry. Leading factories and hubs continue to push the boundaries of soccer ball manufacturing, meeting the needs of a global market.

The football industry has transformed the economic landscape of Sialkot. Factories in this city employ thousands of workers. Many families rely on steady jobs in football production for their livelihoods. The industry also supports related sectors, such as packaging, transportation, and machinery maintenance. Other regions in Pakistan and countries like China and India have seen similar benefits. The demand for skilled and unskilled labor continues to rise as the industry expands.

Note: Job opportunities in football manufacturing help reduce unemployment and improve living standards in many communities.

The growth of the football industry has led to significant community development. Factory owners invest in local infrastructure, including schools, clinics, and roads. Workers gain access to better education and healthcare. Many companies support social programs that benefit children and women. These efforts create a positive environment for families and encourage long-term growth. The industry’s presence often brings electricity, clean water, and new technology to previously underserved areas.

The global distribution of footballs has made the sport more accessible. Mass production lowers costs, so more people can afford to buy a soccer ball. Children in remote villages and urban centers alike can play the game. Affordable equipment helps schools and clubs introduce football to new generations. The industry’s focus on quality ensures that even low-cost balls meet safety and performance standards.

Affordable footballs promote physical activity.

More children participate in organized sports.

Communities unite through local matches and tournaments.

The football industry plays a key role in the growth of the global game. Reliable production and efficient distribution allow the sport to reach every continent. International tournaments showcase the best talent and inspire young players. The life cycle of a soccer ball, from factory to field, connects people across cultures. The industry also faces challenges, such as reducing its impact on the environment. Many companies now explore eco-friendly materials and recycling programs to support sustainability.

The journey of a football reflects the power of teamwork, innovation, and community spirit.

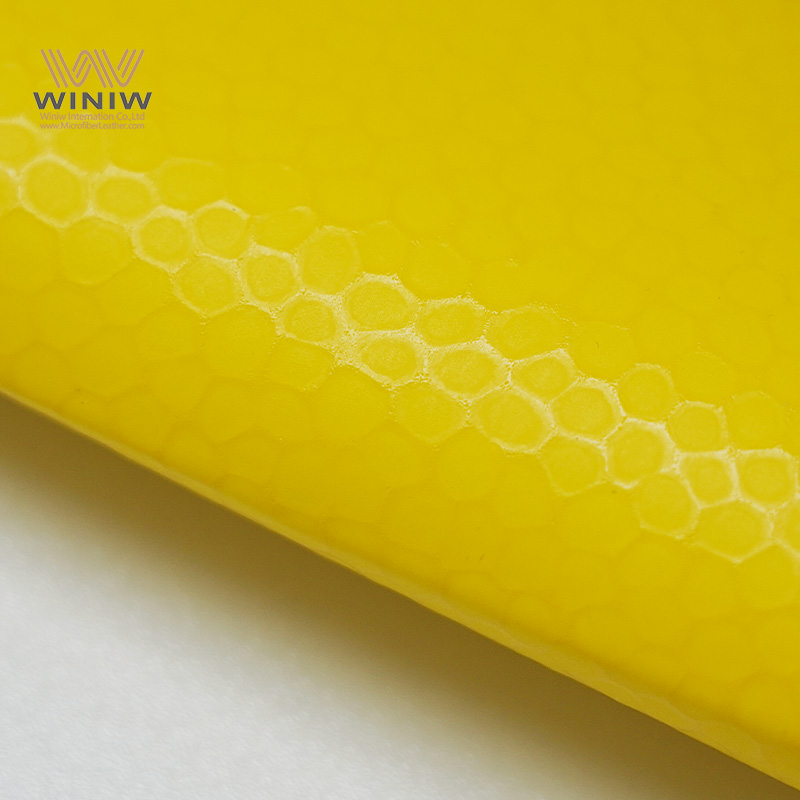

PU football factories face growing pressure to reduce their environmental impact. Many companies now research and develop eco-friendly materials to replace traditional synthetics. They experiment with bio-based polyurethanes and recycled plastics. These new materials help lower emissions and decrease waste during production. Some factories use water-based adhesives instead of harsh chemicals. This shift protects both workers and the environment. Brands also explore biodegradable packaging to further reduce pollution. The life cycle of a soccer ball now includes recycling programs and take-back initiatives. These efforts aim to keep used balls out of landfills and promote a circular economy.

Tip: Choosing footballs made with sustainable materials supports a cleaner planet.

Innovation drives the future of PU football manufacturing. Companies invest in advanced machinery that uses less energy and produces less waste. They design new processes that improve efficiency and quality. Many factories adopt digital tracking systems to monitor resource use and reduce errors. These systems help managers make better decisions and cut costs. Some brands use 3D printing to create prototypes quickly. This technology speeds up product development and allows for more creative designs. Industry leaders also partner with universities and research centers to stay ahead in sustainability and technology.

The PU football manufacturing sector experiences different growth rates across regions. Asia Pacific leads with rapid expansion, as China dominates production and India increases its market share. North America shows steady growth, driven by investment and innovation. Europe focuses on strict regulations and sustainability, with Germany excelling in engineering. Latin America modernizes its factories, with Brazil driving demand. The Middle East and Africa diversify their economies, with the UAE and Saudi Arabia launching major projects. These shifts create new opportunities for factories and workers worldwide.

Asia Pacific: Fastest growth, led by China and India

North America: Innovation and steady investment

Europe: Sustainability and engineering strength

Latin America: Modernization and rising demand

Middle East & Africa: Economic diversification

Automation transforms PU football production. Many factories now use AI-driven machines to improve stitch precision and consistency. Predictive analytics optimize supply chains and manage inventory. Machine learning algorithms detect defects and ensure quality control. Digital twins simulate processes and help with planning. Data-driven decision-making improves both production and logistics. Automation reduces labor costs and increases scalability. Companies invest in AI and IoT to boost innovation and stay competitive. These advances shape the future of the industry and help reduce the environmental impact of manufacturing.

Note: Technology and automation will continue to change how footballs are made, making the process faster, smarter, and more sustainable.

PU football factories began with innovation in Germany and grew through Sialkot’s leadership. The shift to polyurethane changed how the world plays football. These factories support jobs, community growth, and global sports culture. Looking ahead, the industry will see:

Smart systems and new product designs

Higher safety standards

Supply chain and cost challenges

More regulations

This journey shows how tradition and technology shape the future of the game.

PU stands for polyurethane. Manufacturers use this synthetic material to make football covers. Polyurethane offers durability, water resistance, and a soft touch. These qualities help footballs perform well in different weather conditions and last longer than traditional leather balls.

Factories switched to PU because it resists water, keeps its shape, and costs less to produce. Players also prefer PU footballs for their consistent performance. This change made footballs more affordable and accessible worldwide.

Pakistan leads global PU football production. Sialkot, a city in Pakistan, supplies millions of footballs each year. Many international tournaments use balls made in Sialkot. The city’s skilled workforce and advanced factories drive its success.

Factories use strict quality control systems. Workers test footballs for size, weight, and durability. Many factories follow FIFA standards. Some use machines to check for defects. This process ensures each ball meets international requirements.

Many companies now develop eco-friendly PU materials. They use recycled plastics and water-based adhesives. Some brands also offer recycling programs for old footballs. These efforts help reduce the environmental impact of football production.

|

Feature |

Hand-Stitched |

Machine-Stitched |

|---|---|---|

|

Durability |

High |

Moderate to High |

|

Cost |

Higher |

Lower |

|

Use |

Professional games |

Training, recreation |

Hand-stitched balls often last longer and suit professional matches. Machine-stitched balls work well for practice and casual play.

Factories now use automation, AI, and advanced machinery. These tools speed up production and improve accuracy. Technology also helps reduce waste and energy use. Modern factories can produce more footballs while maintaining high quality.